| Sign In | Join Free | My fnxradio.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My fnxradio.com |

|

Brand Name : Hanpu

Place of Origin : China

Certification : ce,iso

MOQ : 1set

Price : 100000

Packaging Details : Packing in wooden case

Delivery Time : 90days-150days

Model Number : mvr

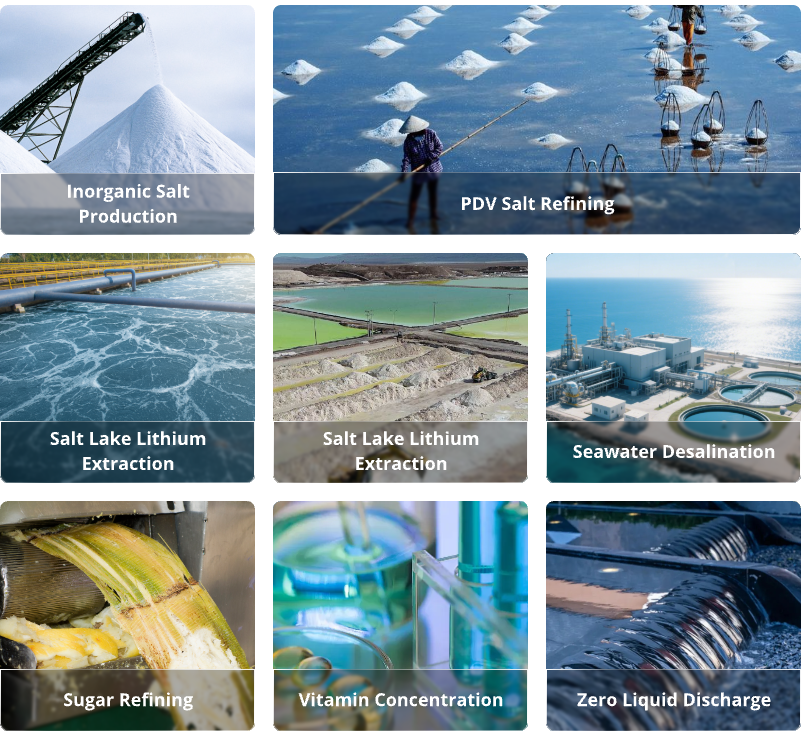

Engineer-to-order MVR (Mechanical Vapor Recompression) evaporator with a customizable operating temperature window to fit heat-sensitive products, viscous concentrates, and high-salinity streams. By recompressing secondary vapor as the heating medium and precisely controlling ΔT and boiling point, the system delivers energy-efficient evaporation, stable quality, and predictable OPEX across diverse processes.

Secondary vapor is mechanically compressed to elevate saturation temperature, then reused as the primary heat source. Tight control of ΔT/LMTD and residence time maximizes heat-transfer efficiency, limits scaling, and preserves product attributes.

Closed-loop regulation of level, ΔT, pressure, and conductivity; interlocks for compressor/VFD, vacuum/NCG handling, and condensate quality guard. Optional AFE/harmonic filters for power-quality compliance.

Hygienic, drainable layouts with validated CIP; surface finishes suited to food/chemical duties. Anti-scale dosing available for high-salinity feeds and long campaigns.

| Parameter | Typical Range* |

|---|---|

| Operation | Continuous, 24/7 |

| Custom temperature window | Low-temp vacuum (e.g., 45–75 °C film) to higher ΔT modes (e.g., 70–95 °C), duty-dependent |

| Electric use (MVR) | ~15–40 kWh per ton of water evaporated (duty/CR dependent) |

| Fresh steam demand | Very low after start-up (backup/ancillary only) |

| Turndown | 50–100% with stable ΔT and product quality |

| Availability | ≥95–98% with redundancy and planned CIP |

| Materials | SS316L / duplex; Ti/Hastelloy on request |

*Actual performance depends on feed characteristics, viscosity, compression ratio, and heat-transfer design.

Yes. Recipe-based temperature/ΔT programs adjust compressor speed and heat-exchange duty for each product.

Vacuum operation lowers boiling point; uniform thin-film/forced-circulation and tight ΔT control prevent hot spots.

We combine optimized LMTD, velocity, anti-scale dosing, and scheduled CIP; materials can be upgraded for corrosion resistance.

|

|

Customized Temperature Range MVR Evaporator For Energy Efficient Evaporation Process Images |